Pottery pollutants

Naylor Industries is an industrial potter producing clay drainage pipes. In 2005, ASK was involved in assessing emissions of pollutants from kilns at the company’s Clough Green site in Barnsley. Through modelling, ASK was able to circumvent the need for a much more expensive direct monitoring exercise.

The case:

Naylor’s Clough Green operations include various kilns and driers, which produce fumes and pollutants that are exhausted through stacks. In particular, local authorities were concerned about levels of fluorides, chlorides, nitrogen dioxide, sulphur dioxide and particulate matter. However, monitoring pollutants was complicated by the awkward location of the stacks on the roof of the building, making it impossible to take direct measurements without erecting prohibitively expensive scaffolding.

ASK’s involvement:

ASK, in collaboration with SEQM, was tasked with carrying out an assessment of emission levels, both at ground level close to the buildings and outside the premises. Our consultants undertook a preliminary assessment using raw data from a previous emissions report, adapting the data to account for the intermittent use of each kiln or dryer. Having concluded that a more detailed assessment was needed, they went on to produce an air dispersion model using meteorological data from a nearby monitoring station.

The result:

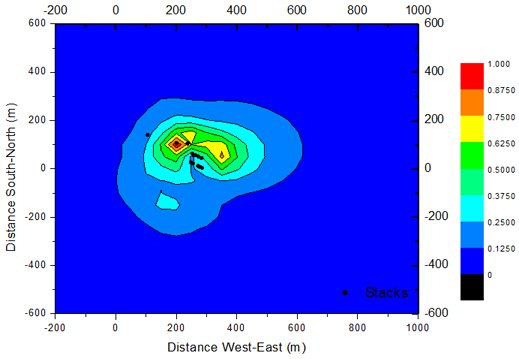

All significant fallout appeared to be constrained to a small area around the stacks. ASK concluded that there was no significant pollutant concentration outside the site and as a result local authorities were satisfied that further measures to curb pollution were unnecessary. The maps produced by ASK show the low extent of the pollution at a fraction of the cost of direct measurements.

Map showing average concentrations of NO as modelled by ASK